What is a mag drive pump?

Magnetic drive pumps have a special sealless design that is suitable for pumping corrosive and dangerous liquids thanks to the high chemical resistance and to the absence of leakage and emissions. The structure is really simple and it requires very little maintenance with consequent savings in terms of repairing, spare parts and machine downtime costs during the pump life.

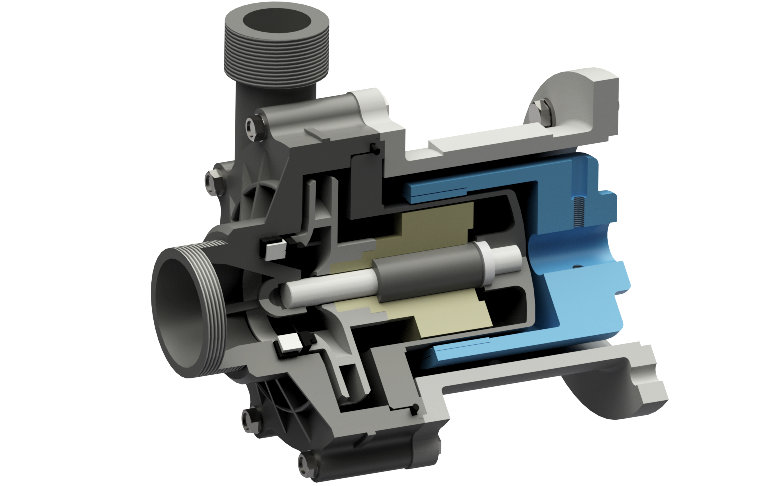

In magnetic pumps, there is an external magnet which is connected to the shaft of the electric motor.

How does a magnetic drive pump work?

The operation of a magnetic drive pump is based on a simple and effective principle. The synchronous motion is transmitted from the motor to the rotor (consisting of the internal magnet and the impeller) through the external magnet. The two magnets never come into contact, they are moved by the magnetic field only.

The impeller connected to the internal magnet spins around a static shaft and the liquid moves through the pump.

The whole hydraulic part is hermetically sealed: in the space between the magnets there is a rear casing which closes on the pump head and prevents the pumped liquid from coming out of the pump.